PRE-ELEC® electrically conductive plastics

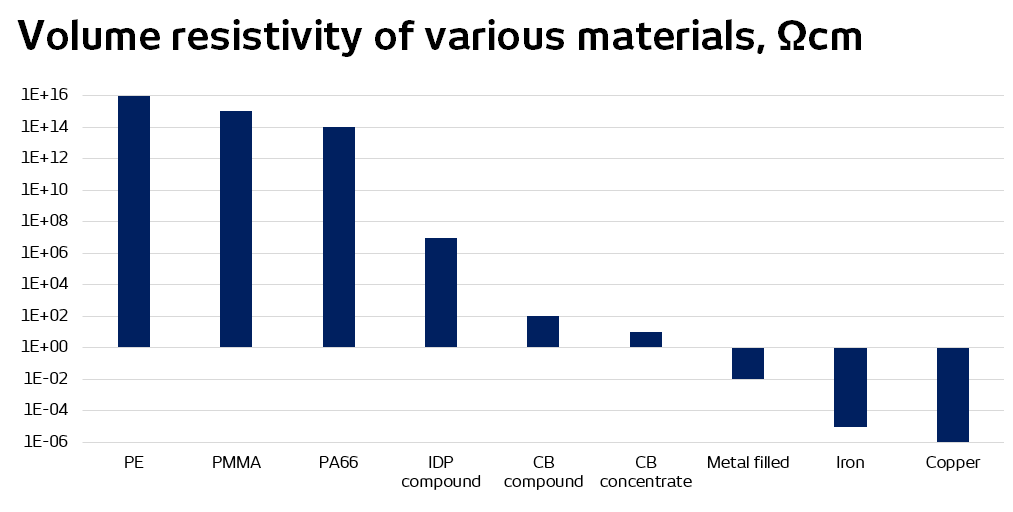

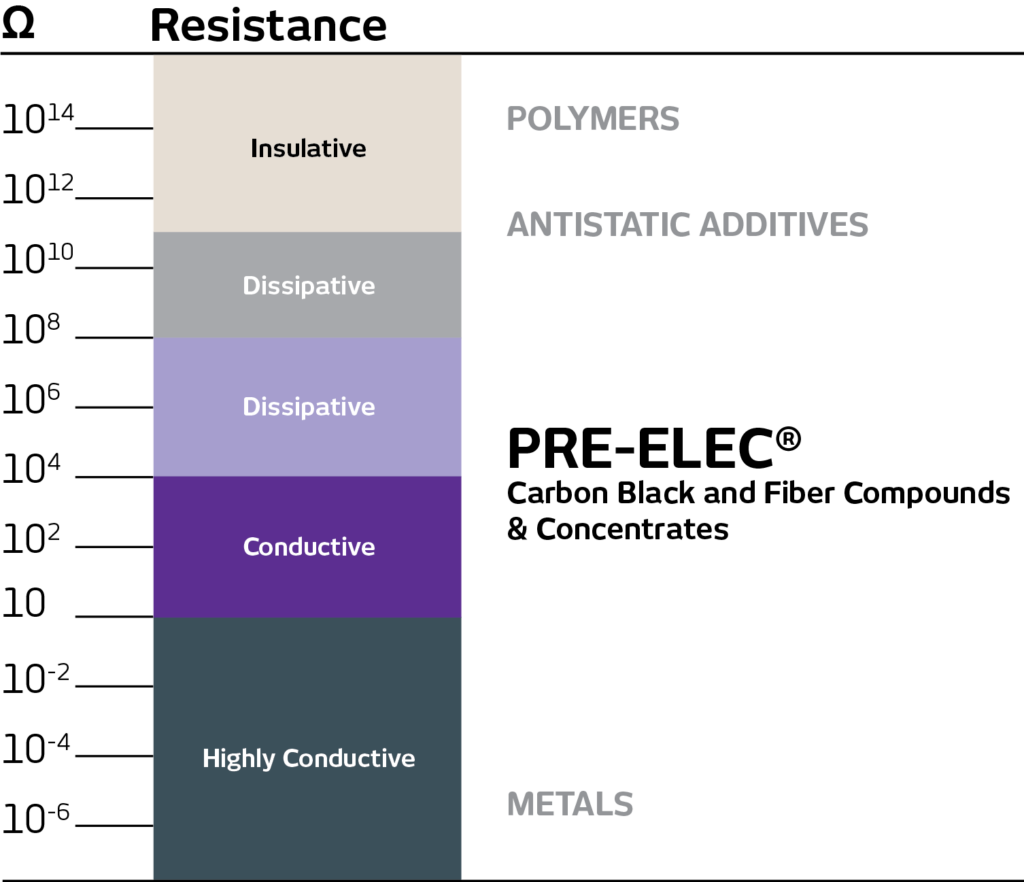

Typically, plastics have insulative nature with resistance of over 1011 ohm. Premix’s electrically conductive plastic compounds contain carbon black (or carbon fibre) which lowers their resistance substantially. They are not as conductive as metals, but very useful as a replacement in many applications, as they are lighter and cheaper, corrosion resistant, and easy to process into different shapes.

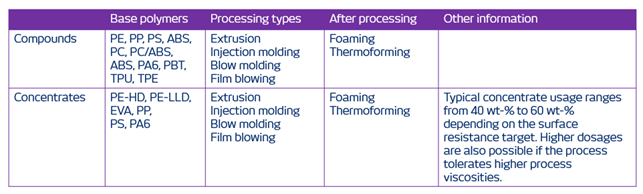

Material Types

- Conductive Polymers

Premix’s electrically conductive plastics can be used in -

- ESD packaging and ESD environments

- ATEX environments

- EMI shielding

- Liquid level detection

- Sensor technologies

ESD packaging and ESD environments

Modern electronics with very small-scale components can break, damage or malfunction because of unintended electrostatic discharges (ESD). For this reason, electronics need to be stored and transported in packaging which protects them from ESD. Also, environments where electronics are produced and used, need ESD protection.

Premix plastics are a good solution for packaging materials for storage and transportation. They can also be used in equipment used in ESD protected environments.

ATEX environments

In environments where there are present flammable or explosive materials that easily ignite (dust, fumes and classified chemicals), electrostatic discharge can even cause explosions. Using conductive materials, such as Premix’s compounds, helps minimizing the risk of electrostatic discharges.

EMI shielding

Fragile electronics are also vulnerable to electromagnetic interference (EMI), which can cause breakage, damage, or malfunction. Electrically conductive plastics can be used in EMI shielding which prevents the electromagnetic interference influencing the electronics.

Liquid level detection

Premix’s electrically conductive plastics has also been used very successfully in liquid level detection, for example in in-vitro diagnostics.

Signal transfer

Electrically conductive plastics can be used in safety edges, body monitoring devices, and other wearable applications. They also provide safety for passengers in transportation, hospitals, and other care settings and can be used in sports applications.

Controlling static electricity

Electrical conductivity can be added to plastics using various additives, but carbon black has become the most widely used and established electrically conductive additive since it is a permanent property for the material. The PRE-ELEC® carbon black and fibre compounds and concentrates produced by Premix Group are designed to provide reliable and consistent electrical conductivity for various applications across multiple industries. The PRE-ELEC® product line is known for its versatility and high performance. The products typically have much lower surface resistance than 109 ohms and can be customised to fulfil specific requirements.

Premix introduced their first electrically conductive plastic compound in 1983 as one of the first companies in the world. Today, the PRE-ELEC® product family covers wide areas of the conductivity spectrum and a large selection of base polymers.